Industry and engineering

Active Light

- Staff at the centre of lighting design – Human Centric Lighting

- The visual, emotional and biological needs of humans working both at night and during the day are taken into account

- Safety, precision and quality are encouraged

- Innovative sensor technology for activity-based lighting that automatically adapts to the user scenario

Industry and engineering

Challenges and focus topics in your project design

Production processes change at increasingly shorter intervals – rooms regularly have to satisfy different utilisation scenarios and visual requirements.

- Lighting systems have to be highly flexible

- Quick changes to layouts

- Minimising production downtimes

- Minimising production downtimes

The job market is influenced by high education standards and demographic changes.

- Companies must respond to these changes and adapt lighting to increasingly complex work processes and the individual needs of employees

- The connection and communication of people, machines, systems and products ensures a further increase in productivity in the form of reduced production times, data analysis, as well as decreased error rates and work-related accidents

Industry and engineering

Challenges and focus topics in your project design

The energy requirements in industrial companies are high due to the long operating and production times.

- A negative carbon footprint and increasing energy costs

- The right lighting and control system considerably contributes to the optimisation of energy resources

- Energy-efficient, dimmable LED luminaires can cut power consumption by up to 25 percent in comparison to conventional lighting solutions

- The intelligent use of presence and daylight sensors and time management systems reduces the need for artificial light even further

Industrial and craft businesses are very diverse and characterised by very different environmental conditions – the lighting requirements also vary accordingly.

- The detection of the prevailing environmental influences plays an increasingly important role in choosing the right lighting, for example:

- temperature ranges

- moisture and dirt accumulation

- cleaning procedure

- Chemically contaminated ambient atmosphere

- Checklists for detecting the basic conditions in industrial projects as assistance

Industry and engineering

Logistics

- Maintenance work in high logistics warehouses is time-consuming and expensive

- Durable LED luminaires minimise the need for maintenance work

- Innovative designs reduce dirt accumulation, support the cooling of luminaires and make cleaning easier

- High energy consumption due to operating times and room sizes – at least 20 percent of the operating costs of a logistics facility are required for lighting

- Costs are reduced with efficient LED luminaires with targeted light direction

- Lighting management systems with corridor functions reduce lighting usage times in areas that are only occasionally used by people

- Glare for forklift drivers when loading and unloading high shelves

- Ideal light quality with good glare suppression has a positive effect on productivity and motivation and increases safety

- Narrow-beam optics for uniform vertical illumination of the shelves in high-bay warehouses; at the same time, horizontal transportation areas are well illuminated

- Track systems are perfect for quickly reacting to modified layouts

- If LED optics are replaced, the general appearance of the luminaires remains unchanged despite the different light distribution

Industry and engineering

Metal working

- A wide range of visual tasks in the metal industry: rough jobs and fine inspection work close together despite individual lighting requirements

- Disruptive glare by reflection on reflective materials can be minimised with uniform light distribution and the correct luminaire arrangement

- Luminaires are exposed to coolants, oil vapours and metal dust

- Luminaires made of PMMA with high IP protection classes offer maximum robustness and prevent the penetration of foreign objects

- Industrial LED luminaires from Zumtobel are specially designed for demanding environments and are equipped for a long service life with the lowest possible reduction in luminous flux

- High degrees of protection and optimised luminaire surfaces minimise the accumulation of dirt, and cleaning and service intervals can be prolonged

- If tasks in the production area change, lighting conditions must be adapted appropriately

- Track systems are highly flexible and adjustable – the position, type and number of luminaires can be changed quickly and simply

Industry and engineering

Automotive

- Shiny metal surfaces carry the risk of direct glare and glare by reflection, which have a negative impact on error rates, concentration and fatigue

- To reduce disruptive light reflections and the subjective sensation of glare, luminaires with uniform, homogeneous light-emitting surfaces are recommended

- Lateral and parallel arrangement of luminaires to the production line reduces undesired light reflections even further

- Replacing lamps and luminaire parts can be costly and time-consuming if production has to be interrupted or the areas are difficult to reach

- Durable LED luminaires with higher degrees of protection and well-thought-out designs help to increase service intervals and reduce maintenance costs

- Silicones influence the wettability of material surfaces – coating processes are impaired, visible defects occur

- Strict regulations in the automotive industry often prohibit the use of luminaires containing silicone in order to minimise the risk of contamination

- Using a higher degree of protection of at least IP5X is recommended for optics and LEDs

- Contamination of and damage to the luminaire are avoided since flying sparks do not penetrate the housing during cutting work

- Energy requirements for lighting in large production halls are high due to the necessary high lumen packages

- Clear energy savings through the use of dimmable LED luminaires

Industry and engineering

Food

- Lighting is subject to strict guidelines in relation to product design and quality

- The minimum standards for safe production of food products are determined by standards and concepts, such as IFS, BRC or HACCP

- Protection against falling splinters

- Surfaces are easy to clean

- There are often very high temperatures in production areas and extreme minus temperatures for areas in which food is stored

- Zumtobel specially developed products for the food industry designed for long-term use under extreme conditions from -40°C up to +50°C

- Visual checks before packaging to check whether products meet freshness and quality requirements

- The use of light sources with high colour rendering guarantees reliable assessment of the smallest colour nuances

Industry and engineering

Chemicals and pharmaceuticals

- High illuminance and low glare values for demanding visual tasks in laboratories

- Disruptive light reflections can be reduced by luminaires with homogeneous light-emitting surfaces

- Individually adjustable workplace luminaires supplement the general lighting concept

- More and more products are produced in clean rooms in accordance with the requirements of DIN EN ISO 14644 or GMP

- Luminaires must meet the following requirements in these strictly controlled areas:

- Hygienic design due to the smoothest possible surface, high IP degree of protection against dust or moisture penetration into the luminaire housing

- Resistant surfaces for regular cleaning and/or disinfection (light sources must be resistant to aggressive cleaning agents and biologically resistant)

- Maintenance work can be a complex task in clean rooms because clean room qualification has to be ensured and validated again

- Clean room luminaires should also be capable of being maintained from above technical areas so as not to impair clean room integrity and to minimise maintenance costs

Industry and engineering

Car parks and quality inspection

- Optimum lighting conditions are a prerequisite for this

- In addition to general lighting, workplace lighting that is adapted to the inspection activity is used (e. g. with increased illuminance or special light colour)

- A combination of an energy-efficient LED lighting solution and corridor-function control system keeps operating costs low

- Vertical illuminance is crucial for safe parking and safely crossing driving lanes

- Light distribution should be as wide as possible for uniform illumination due to the low overall height

- Pleasant room atmosphere due to slight indirect share

Industry and engineering

Wood, paper, textiles and agriculture

- Luminaires with a limited surface temperature and higher degree of protection for areas at risk of fire (marked with "D")

- The label confirms that the luminaire’s outer surfaces, on which easily flammable substances can accumulate, do not exceed the limit temperatures specified in EN 60598-2-24 and provide the required protection against the penetration of solid and liquid foreign objects

- Luminaires with an extra degree of protection and materials resistant against gases and aggressive cleaning agents released in barns (especially*principally PMMA)

- Energy-saving LED lighting solution for large halls and long operating times

Industry and engineering

10. Project design principles: typical light distribution in industry

- Uniform, efficient illumination of large areas

- Lighting solution works just as well after alterations

- Wide beam or narrow beam, depending on the room height

- Intense, even illumination of vertical surfaces, e.g. shelves, machines with lateral visual tasks, large objects such as aeroplanes, trains, etc.

- Reflection-free, uniform light with high illuminance for undisturbed work

Industry and engineering

Project design principles: typical light distribution in industry

- Light has to be precisely adjusted to the task at hand in terms of light colour (colour rendering), light direction, amount of light and the position of the lighting

- Additional workplace-related lighting

- Flat, shadowless light

- Different colour temperatures

- Uniform, efficient illumination of large areas

- Lighting solution works just as well after alterations

- Wide beam or narrow beam, depending on the room height

- Even illumination of low spaces (e.g. underground garages)

- Additional indirect light share for ceiling illumination for a friendly appearance

Industry and engineering

References

-

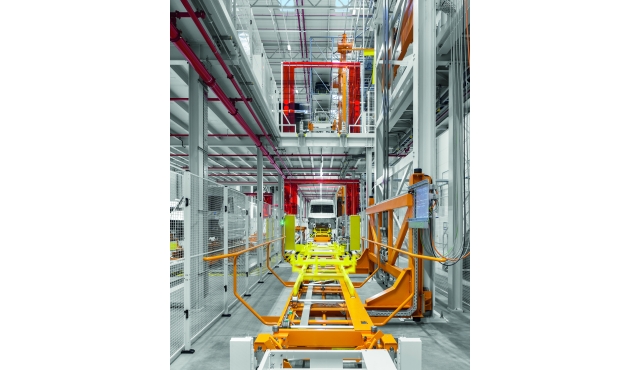

VW Crafter Factory

VW Crafter Factory

Wrzesnia, Poland -

Messe Dornbirn

Messe Dornbirn

Dornbirn, Austria -

Audi factory

Audi factory

Győr, Hungary -

Gebrüder Weiss

Gebrüder Weiss

Pöchlarn, Austria -

Construction of Hall 100, VW Motor Works

Construction of Hall 100, VW Motor Works

Chemnitz, Germany -

Ferrari Classiche

Ferrari Classiche

Maranello, Italy -

Technogym spa

Technogym spa

Cesena, Italy -

Risse + Wilke Kaltband GmbH & Co.

Risse + Wilke Kaltband GmbH & Co.

Iserlohn, Germany -

Alexander Bürkle GmbH & Co.KG

Alexander Bürkle GmbH & Co.KG

Freiburg, Germany -

ASEAG Verkehrsbetriebe

ASEAG Verkehrsbetriebe

Aachen, Germany -

Parker Hannifin & Co.KG

Parker Hannifin & Co.KG

Bielefeld, Germany -

Technoalpin Bolzano

Technoalpin Bolzano

Bolzano, Italy

| Owner: | VW Crafter Vehicles, Wrzesnia (PL) |

| Photos: | Henning Moser |

Volkswagen Commercial Vehicles opened a new production plant in the Polish city of Wrzesnia at the end of October 2016. The factory manufactures the latest generation of the Volkswagen Crafter and the similar TGE model from MAN. The site, which covers an area of around 220 hectares, has the capacity to produce up to 100,000 vehicles per year and incorporates a modern paint shop and halls for bodywork construction and assembly, as well as a supplier park with logistics operations. Thanks to an innovative full LED solution from Zumtobel, the factory has established itself as a leader in lighting efficiency within the VW Group.

Zumtobel supports the “Think Blue-Factory” concept

Zumtobel was awarded the contract for this major project in Wrzesnia in 2015 following the submission of a detailed lighting concept. Alongside luminaires and controls for the assembly and production halls, the complete solution includes efficient lighting for the offices, high-bay storage facilities and outdoor areas. Safety lighting also represented a key cornerstone of the project. Zumtobel was in close contact with specialist planners from Volkswagen Commercial Vehicles throughout the implementation phase, helping the Austrian lighting solutions supplier to precisely fulfil the specific requirements of the client. Initial Volkswagen planning was based largely around conventional lighting, but efficiency calculations and the technological progress of LED technology at Zumtobel soon convinced the planners to realise the entire project with LED. The decision prompted VW to classify the new production facility as a “Think Blue-Factory”. This programme is designed to encourage plants to use resources more efficiently, reducing emissions and energy usage while minimising both water consumption and waste. “We are delighted that Volkswagen Commercial Vehicles has opted for a complete LED approach. Together we have been able to create one of the most efficient production plants in the VW Group in terms of lighting,” explained Frank Oevermann, Key Account Manager Automotive at Zumtobel. Matthias Strutz, Electrical Power Supply Planning at Volkswagen in Wolfsburg, added: “The new factory represents a clear statement in terms of environmental protection. We are really benefitting from the decision to use only LED – both ecologically and economically. LED solutions extend the service life and cut maintenance and operating costs, while at the same time ensuring a constant lighting intensity over the entire service life.”

Lighting solution in detail

The largest part of the project is taken care of by the TECTON continuous-row system, which reduces energy consumption by 50 percent compared to T16 trunking. A total of 16,000 TECTON C LED luminaires are installed over a length of around 40 kilometres. This continuous-row luminaire is optimised for a variety of different racking and surface lighting tasks, providing the perfect solution for the dedicated Volkswagen Crafter manufacturing and assembly facilities. The current conducting section is mounted in the TECTON trunking, enabling the versatile rail to offer seamless functions such as power supply, lighting controls and connection to the emergency lighting network. The CRAFT high-bay fitting used by Zumtobel in the paint shop and higher halls can be quickly and easily installed on the TECTON system. Based on 15,000 continuous-row 40W LED luminaires and 6000 operating hours, Volkswagen Commercial Vehicles is now saving 3420 megawatt hours (MWh) and 1920 tonnes of carbon dioxide (CO2) each year at the Polish plant.

The offices feature the recessed MIREL evolution luminaire and the PANOS downlight series, which ensure uniform illumination of the working areas and create precise accents that accentuate the interior architecture.

R2L2 LED lanterns and ForceLED fittings from Thorn light the car park and exterior façade. The high-performance optics utilised in the R2L2 street lantern offer excellent energy efficiency and a choice of distributions for precise light control without wasteful stray light. The compact, dust-tight and moisture-proof ForceLED solution incorporates an aluminium housing for added resistance and supplements the general exterior illumination of the building with pleasant accents.

The ONLITE RESCLITE from Zumtobel has been trusted to highlight the escape routes. In line with EN 1838, the luminaire provides the necessary orientation in the event of an emergency and also offers anti-panic lighting. The emergency lighting is monitored by LITECOM, a lighting management solution from Zumtobel Group Services (ZGS).

Additional lighting tasks are carried out by products from Zumtobel’s PERLUCE and ONDARIA series and the Thorn Satin range, alongside the KXA-2 and KXB explosion-proof linear luminaires. As a technology partner, Tridonic has supplied component solutions such as drivers and LED light sources for the luminaires. A specific Constant Light Output (CLO) setting was configured for the entire luminaire installation during the manufacturing stage. The CLO function, which is now standard for all industrial luminaires used by Volkswagen, ensures a uniform reduction in the luminous flux over the stated lifetime.

Zumtobel. The Light.

share it

| Architect: | Marte.Marte |

The special challenge for the lighting solution is not only the variety of functional areas but also the incredible dimensions of the halls, boasting lengths of 75 metres and room heights of 11 metres. Exhibitions, trade fairs, concerts, company parties or congresses – the lighting has to meet the exacting demands of vastly contrasting events. In addition, the solutions need to be efficient and should fulfil specific architectural requirements, such as the visual staging of prominent sections of the external façade and the precise, even and flexible illumination of the entire halls – despite the enormous ceiling heights. Zumtobel solved these tricky tasks with innovative customised fittings from the TECTON Balanced White and PANOS infinity lighting ranges.

The versatile TECTON Balanced White continuous-row system – a product from the new “the editions - extended collection” special portfolio – allows individual adaptation of the colour temperature to reflect the particular application. This ensures consistently high levels of light quality and enhanced visitor well-being – no matter how the space is used. TECTON is the world's first continuous-row system to feature an 11-pole current conducting section installed in the trunking. All key functions are seamlessly integrated into the versatile rail, including power supply, lighting controls and emergency lighting.

The stairwells and the red foyer are illuminated using the PANOS infinity architectural lighting system, offering a leading combination of versatility and energy efficiency. The round LED recessed downlights comprehensively cover every aspect of sophisticated lighting tasks. The light is characterised by a pleasant colour temperature, making it very similar to daylight. With a system luminous efficiency of up to 100 lumens per watt, PANOS infinity is twice as efficient as conventional downlights. Zumtobel produced the fittings for the Messe Dornbirn in the customised tones of black and red, supporting a solution that integrates seamlessly into the overall colour scheme of the architecture.

Zumtobel. The Light.

share it

| Planning office: | IBB Blomeier (DE), IB Kaulich & Hofman (DE), Ingenieurbüro Michael Huber (DE) |

By far the largest share of the order volume is made up by the TECTON continuous-row lighting system, which is able to meet a huge variety of lighting requirements and adjust to the demands of specific visual tasks with more flexibility than any other system. In the assembly bays, approx. 140 kilometres of the TECTON continuous-row lighting system were installed. Ambient lighting in the factory hall is provided by Zumtobel's TECTON luminaires fitted with ST reflectors designed for rooms of up to 10 m in height. In order to ensure perfect illumination of the 18 m high short-term storage facility and the logistics section, TECTON SH reflectors boasting extremely narrow-beam light distribution are used. In highly sensitive rooms such as the laboratory, the TECTON IP50 luminaires installed comply with the prescribed clean-room requirements.

The LED emergency lighting system implemented by Zumtobel is a sophisticated custom solution that allows communication between the existing external emergency lighting system and Zumtobel's emergency luminaires. For this purpose, the ONLITE RESCLITE LED emergency luminaire was elaborately reprogrammed. It is the only emergency luminaire currently available on the market that is suitable for mounting heights between 2.2 m and 20 m, nevertheless requiring only a minimum of energy. In addition, ONLITE ECOSIGN escape-sign luminaires were installed at Audi Hungaria's Plant 2 as well.

Other Zumtobel luminaires installed within Plant 2 include the 2 x 49 W TECTON laser cabin luminaires featuring IP50 rating and a special reflector as well as the CLEAN clean-room luminaire for wind tunnel illumination. Both were implemented as custom solutions to meet the special requirements of the new factory building. In the canteen and the restaurant, CARDAN recessed LED luminaires in various colour temperatures were installed. Ambient lighting of the dining rooms is provided by Zumtobel's SCONFINE pendant LED luminaires. The canopies and splash-guard area are illuminated by SCUBA moisture-proof luminaires. LED downlights of the PANOS infinity and CREDOS ranges brighten up the factory's staff lounges. In the offices of Plant 2, LED luminaires of the LIGHT FIELDS range provide perfect task lighting at the workstations.

Zumtobel. The Light.

share it

| Owner: | Gebrüder Weiss, Lauterach (AT) |

Due to their high energy efficiency, LEDs have played a major role in building new and refurbishing existing buildings of the logistics hubs of Gebrüder Weiss in compliance with environmental considerations. For the Pöchlarn refurbishment project, it was however not only for environmental but also for functional and economic reasons that the decision-makers opted for TECTON LED: “We were looking for a solution suitable for an industrial application which we could use as a basic system and flexibly adjust to a variety of standard specifications for illuminating different areas of the hall,” outlines Markus Nigsch, head of real-estate and facility management at Gebrüder Weiss, the most important requirements. For example, it should be no problem to install presence detectors. Above all, one of the arguments in favour of the Zumtobel system were the low maintenance efforts required, as the design of the continuous row system and the trunking follows the principle of plug and play. Tools are neither required for connecting trunking elements nor for replacing luminaires. The significantly extended maintenance cycle of the solution is also due to the LEDs' long service life of an average of ten years.

Markus Nigsch underlines the direct impact of TECTON LED on the CO2 footprint of the Pöchlarn freight hub by making a direct comparison with the discarded fluorescent lamp solution: “We have been able to reduce annual power consumption from 1.2 million to less than 465,000 kilowatt hours. This results in a reduction of CO2 emissions related to lighting by almost 139 tonnes per year – amounting to just 38.6 per cent of the former level.”

Similarly positive results were achieved with LED solutions provided by Zumtobel also in large-scale projects of Gebrüder Weiss regarding new buildings – for instance at the Wels logistics centre, at the Jeneč site in the Czech Republic, and in the new warehouse and head office at the company's headquarters in Lauterach.

Zumtobel. The Light.

share it

| Owner: | Volkswagen AG, Wolfsburg (DE) |

| Architect: | IC-L Ingenieur Consulting Langenhagen GmbH & Co. KG Langenhagen (DE) |

| Lighting design: | Volkswagen AG, Wolfsburg (DE) |

| Electrical consultants: | Volkswagen Elektroplanung, Wolfsburg (DE) |

| Electrical installations: | Voith Industrial Services GmbH, Chemnitz (DE) |

In November 2013 the project was awarded the gold certificate of the German Society for Sustainable Construction (DGNB). The new hall therefore meets the stringent criteria of the DGNB, which is based on a comprehensive consideration of economy, ecology and user convenience.

According to the motto “More sustainability, less environmental impact” various workshops have been established in Chemnitz to intensively strive for ways to reduce energy consumption. A comprehensive analysis of the production process is the key to this endeavour. Above all, the production systems are analysed based on energy efficiency to make use of every potential for optimisation. The lighting system with innovative LED technology makes a major contribution in this respect.

In the mechanical production process, high-tech machining centres and complex, virtually fully automatic line controllers define the production process. This requires homogeneous illumination with an average of 300 lux. Another requirement was dimmable luminaires and integration of emergency lighting in the continuous row lighting. Zumtobel was able to optimally fulfil all of these requirements with the TECTON LED continuous-row lighting system and integrated emergency luminaires. DIMLITE modules ensure efficient control of the continuous row lighting.

Zumtobel. The Light.

share it

| Owner: | Ferrari s.p.a., Maranello (IT) |

| Architect: | Arch. Simona Franci, Fortebìs Group, Rome (IT) |

| Lighting design: | Arch. Francesca nasi, Carpi (IT) |

| Electrical consultants: | Prospazio, Modena (IT) |

Daylight, a high lighting level of 1000 lux and an intermediate light colour of 4000 K aid productivity by perfectly meeting the demands for meticulous small detailed work. The general dimmability of LED luminaires makes it easy to adjust the lighting to cope with various activities and usage periods. This extra reliability is achieved thanks to the LED's long service life and IP50 rating. Emergency lighting has been integrated into the general lighting system. Every third TECTON LED is an emergency luminaire.

Zumtobel. The Light.

share it

| Owner: | Technogym spa, Cesena (IT) |

| Architect: | Antonio Citterio Patricia Viel and Partners, Milan (IT) |

| Lighting design: | Antonio Citterio Patricia Viel and Partners, Milan (IT) |

| Electrical consultants: | Studio R.B. Engineering, Modena (IT) |

| Electrical installations: | F.lli Franchini, Rimini (IT) |

been superseded. Today, the company has 2,200 employees and it’s products can be found in 50,000 fitness studios and more than 30 million private households throughout the world. This development is the result of a far-sighted realignment: in addition to muscle building, the machines were to fulfil the purpose of boosting well-being. Since then, the idea of wellness has led to product developments for which scientists from MIT and other experts are often consulted. Also, the company headquarters in Cesena, which opened in 2012, is anything but a normal factory with an adjoining administrative building. Only a few kilometres from Nerio Alessandri’s old garage now stands a “Wellness Campus”, where products are produced, researched and discussed, with no small amount of perspiration. “We are not only a manufacturer of sports equipment, but also a service agency,” says Roberto Laureti, the technical manager responsible for building control and maintenance at Technogym. About 25,000 visitors are received every year on the 150,000 m2 company grounds, which includes a research center, a library, a fitness club, a health food restaurant and a conference center with 600 seats. Several hundred courses are offered – from classic training for sports trainers to motivation and leadership training for managers.

The task faced by the Milan-based architect Antonio Citterio and his partner Patricia Viel was as follows: To translate wellness into a structural framework that combines sustainable, eco-friendly construction with a high quality of well-being. That no ordinary assembly hall is to be expected here is immediately apparent. The 60,000 m2 building is situated in the midst of a rolling park landscape and is crowned by a wave-shaped curved wooden roof. “The architecture plays a crucial role in the light planning,” Roberto Laureti emphasises. The entire building is divided into eight segments, each with a width of 18 m and a length of between 200 and 280 m. Seven segments combine to form the 32,000 m2 production hall and warehouse, where assembly of the machines takes place. Continuous row lighting suspended from the ceiling extends the entire length of the hall, providing a brightness of 390 Lux for the assembly area. In the storage areas, located upstream and downstream of the production area, the brightness is reduced to 150 Lux. Sensors are used to adapt the intensity of the lighting based on the daylight conditions. The skylights, which follow the wave shape of the roof, ensure that even the middle of the hall is flooded with sunlight. In the afternoon hours and on overcast days the intensity of the artificial light is adapted to the reduced natural light, to create a constant perfect interplay of the two light sources, for well-balanced and pleasant lighting of the production hall.

The production area is separated from the 11,000 m2 administrative building by a road flanked with trees. The slight curve of the wooden roof on the south side of the four-story building has a dual purpose: it not only provides an inviting gesture for arriving visitors, but also protects the fully windowed offices against direct sunlight and overheating. The offices are characterised by openness. The conference rooms, which have windows on all sides, feature round bean bags as seating for employees and guests, and the workplace is designed as an “open space” office. Narrow continuous row lighting accents the room, providing a colour temperature of 2,700 K for a warm, pleasant atmosphere. The elliptical “Wellness Center” in the south end of the administrative building houses the public functions of the campus on an area of 4,000 m2. To enter this area, visitors must first descend a spacious spiral staircase that winds through the entire building. While the wooden steps give a down-to-earth appearance, the impression on the bottom side is much different. Together with Zumtobel, Antonio Citterio and Patricia Viel developed a backlit LED solution to create changing colour and light moods. The southern part of the ellipsis houses the fitness centre, which also serves as a showroom for Technogym products. This room, which is flooded with daylight, opens onto the surrounding park with a glass curtain façade over two stories. All of the employees can exercise here during the week, and on weekends their families and friends can use the facilities free of charge.

The company also insists on balanced nutrition for the employees. The restaurant’s cooks use only seasonal vegetables from the surrounding region. Chocolate bars, on the other hand, have been banned from all vending machines. Instead, they are filled daily with fresh salads, fruits and other healthy snacks. The “wellness system key” prevents anyone from exceeding their personal limit. This data storage system records the training results and calculates the calories burned so far on a given day. With each fruit salad from the office vending machines, the number rises, providing a discreet recommendation for more exercise. By now it should be clear: Wellness in Cesena is not an activity that lasts only a few hours. It is an attitude that encompasses one’s entire life.

Zumtobel. The Light.

share it

| Owner: | Risse + Wilke Kaltband GmbH & Co., Iserlohn (DE) |

| Electrical consultants: | Mark-E, Hagen (DE) |

Metal halide lamps were previously used in cold-rolled steel strip producer Risse+Wilke’s manufacturing bay. However, this outmoded, conventional way of producing the quantities of light needed in large, tall industrial buildings does not stand a chance up against modern lighting solutions in terms of quantity or quality. Modern lighting solutions help optimise conditions at the workstations, improve motivation and prevent fatigue, therefore reducing industrial accidents. This is why the cold-rolled steel strip producer decided to modernise the lighting installation in its production plant by installing new high-bay reflector luminaires.

The 545 new VALUEA high-bay reflector luminaires are fitted with state-of-the-art fluorescent lamps and high-performance reflectors. Their premium lighting quality is confirmed by an excellent colour rendition index > 80 and now more uniform illumination. Luminous flux is virtually constant and even ambient temperatures of 35 °C are no problem. The use of advanced, controllable ballasts is a crucial aspect of this high energy efficiency. Dimming alone cuts energy consumption compared with a non-dimmable lighting solution by 30% and daylight-based lighting management increases potential savings further still. Flicker-free light is an additional benefit when using rotating machinery. Unlike conventional high-bay projectors that use 50 Hz technology, fluorescent lamps operate at 22 kHz, thus preventing any strobing.

Risse+Wilke now consume up to 45% less energy after completing their lighting refurbishment project and installing VALUEA and a DIMLITE lighting management system. This simple plug-and-play system makes commissioning much easier: with DIMLITE, the required components are simply hooked up to a base module and started up by an auto setup procedure. The required group control was also implemented straightforwardly so that individual sets of luminaires can be dimmed individually or depending on the amount of daylight available. The fact that lighting control now makes it possible to respond flexibly to changes in the layout of the storage or production area is yet another benefit.

Zumtobel. The Light.

share it

| Owner: | Alexander Bürkle GmbH & Co.KG, Freiburg (DE) |

| Architect: | Freyler Industriebau GmbH, Kenzingen (DE) |

| Electrical consultants: | Planungsgruppe Burgert, Schallstadt (DE) |

| Electrical installations: | El. Geppert, Breisach (DE) |

Alexander Bürkle GmbH have extended their site by building a 2,600 m² warehouse and an adjacent office building. As a participant in Freiburg’s ECOFIT promotion scheme, this Freiburg-based electrical wholesaler seizes every opportunity to ensure environmentally compatible and economically efficient operation by using the very latest technologies. Zumtobel’s innovative lighting concept is making a valuable contribution towards achieving the goal of reducing energy consumption without compromising excellent lighting quality.

The architecture of the new three-storey administrative building was ideal for exploiting the benefits of LEDs. The office premises were built without any columns or supporting elements to ensure flexible floor space usage. Zumtobel developed an equally modern office lighting concept based on a customisedt CRAYON LED downlight solution: 122 square CRAYON LED downlights fitted with 48 W lamps in a special 625 mm size model were installed flush with the ceiling. Their warm light colour (4000 K) not only creates pleasant, uniform ambient lighting; the luminaires also have a long service life, produce colour-stable light, and are maintenance free and dimmable.

The warehouse is characterised by functional, resource-conserving architecture with many skylights that let in as much daylight as possible. Artificial lighting is deliberately only used to achieve the required level of illuminance if there is insufficient natural light. Those responsible opted to use the tried-and-tested TECTON continuous-row lighting system for ambient lighting in the warehouse. This modular continuous row system offers optimal light for industrial applications and guarantees illuminance of 300 lux in conformity with applicable standards. The system can be extended flexibly, and reflectors and emergency luminaires can be added.

CRAYON LED downlights with IP 44 protection were installed in wet locations. This 12 W downlight achieves the same lighting levels as a 50 W halogen lamp or 18 W compact fluorescent lamp. This makes it possible to replace conventional downlights by more efficient, more durable LED luminaires with little effort.

Zumtobel. The Light.

share it

-

CRAYON

CRAYON

-

TECTON

TECTON

| Owner: | ASEAG Verkehrsbetriebe Aachen (DE) |

| Electrical installations: | Frings Elektrotechnik, Alsdorf (DE) |

When you enter Verkehrsbetriebe’s maintenance workshop in Aachen, it's not just the buses that are fascinating - the onlooker’s eye is unerringly drawn to the very bright, pleasant lighting. The fact that this lighting also extremely energy efficient is due to the technology behind the new lighting installation.

In the two spacious workshops, 280 buses belonging to Aachen Strassenbahn- und Energieversorger AG and around 150 buses belonging to other firms are serviced and cleaned. Operating round the clock, lighting accounts for a large proportion of operating costs. The old system created a total installed load of 26,000 W and was operated 18 hours a day. Large skylights are the best way of exploiting natural light.

Thanks to new, more efficient dimmable SCUBA moisture-proof luminaires and T5 light sources, now it only takes 18,000 W to illuminate the workstations in the smaller workshop in conformity with applicable standards at 550 to 600 lux. Each individual SCUBA luminaire is connected to the LUXMATE Professional control system and an external daylight sensor, and is automatically dimmed or switched off as required. Even in cloudy weather, an installed load of 12,000 W is seldom exceeded and when the sun shines the installed load can drop as low as 5000 W! This is equivalent to a saving of more than 60%. That is even before taking into account the additional potential savings provided by presence detectors, which slowly dim and then switch off sets of 3 to 4 luminaires when there is nobody in a particular area. The spacious workshop made it possible to obtain even more impressive savings. The total installed load was reduced from 58,000 W to 30,300 W on average. When the weather is fine, installed load readings of 14,500 W are sometimes displayed on the computer station; this means that the system's payback time is only 2 years.

The emergency lighting was also upgraded to state-of-the-art standards. RESCLITE emergency luminaires with high-power LEDs are fitted on trunking. Thanks to maximum efficiency and perfect light distribution, a few luminaires are enough to provide emergency lighting in conformity with relevant standards, even when they are installed on high ceilings. And yet the powerful LED package requires a minimum of energy. The luminaire's installed load is only 5 W, in non-maintained mode it is even as low as 1.5 W.

Zumtobel. The Light.

share it

-

SCUBA

SCUBA

-

LUXMATE PROFESSIONAL

LUXMATE PROFESSIONAL

| Owner: | Parker Hannifin GmbH & Co.KG, Bielefeld (DE) |

| Architect: | Robert Wiehofsky, Podufal + Wiehofsky, Löhne (DE) |

| Electrical consultants: | Fred Hölters, Elplan Ingenieurgesellschaft, Minden (DE) |

| Electrical installations: | Schlau Elektrotechnik GmbH, Lemgo (DE) |

Parker Hannifin GmbH’s new logistics centre in Bielefeld boasts impressive dimensions - its high-bay storage facility houses 18 m high racks that provide capacity for up to 15,000 pallets. Light must penetrate into the very lowest shelves and provide illuminance levels of 200 lux even there. This is the only way of ensuring that all item barcodes can be scanned quickly and without errors. With its outstanding lighting quality and high energy efficiency, the TECTON continuous-row lighting system impressed people right from the start. Thanks to narrow-beam reflectors and its 1x80 W light source, achieving the required illuminance level poses no problem. At the same time, TECTON’s modular system design and easy installation make it highly adaptable in the event of any subsequent extension or reconstruction of industrial buildings. Emergency lighting was built into the continuous-row lighting system to make sure that sufficient light is available even in an emergency. Three luminaires are installed as emergency luminaires in every aisle on an 11-pole track system.

TECTON luminaires with narrow-beam reflectors are also used in the 8 m high production and dispatch bay. Because the bay runs work in 3 shifts, the lighting is switched on continuously from Monday to Friday. The continuous row systems can be switched on one third or two thirds in order to reduce the lighting level as required and save energy.

Administrative and prestigious areas provide a complete contrast in lighting terms: SCONFINE Linea pendant luminaires, PANOS Q downlights and SLOTLIGHT light lines arranged in a rectangle welcome visitors into an exciting lighting ensemble. Controlled by the LUXMATE Emotion lighting management system, pre-programmed lighting scenarios can be run at the press of a button. Recessed MELLOW LIGHT IV luminaires and KAREA free-standing luminaires conjure up a lighting scene that is similar to daylight in office areas with a pleasant ratio of direct to indirect light that ensures optimal glare-free working conditions. The gentle light from SCONFINE Linea pendant luminaires produces a calm, relaxing atmosphere in the canteen. Large reflective areas provided by suspended curved elements emphasise the pleasant lighting effect achieved.

Zumtobel. The Light.

share it

-

MELLOW LIGHT IV

MELLOW LIGHT IV

-

SCONFINE

SCONFINE

-

PANOS

PANOS

-

TECTON

TECTON

-

KAREA

KAREA

-

SLOTLIGHT infinity

SLOTLIGHT infinity

| Owner: | TechnoAlpin AG |

| Architect: | Arch. Johannes Niederstätter VWN Architects in cooperation with Dr. Roland Baldi, Bolzano (IT) |

| Lighting design: | Studio G GmbH, Bruneck (IT) |

| Electrical consultants: | Studio G GmbH, Bruneck (IT) |

| Electrical installations: | Elektro Gbitz Lorenz, Deutschnofen (IT) |

|

„The lighting played a major role in the design of our new company headquarters. Zumtobel has managed to perfectly meet our requirements in terms of superior lighting quality in a variety of rooms. Zumtobel has turned out to be an indispensable partner, supplying a professional and energy-efficient lighting solution for single-person offices, the conference room and manufacturing through to components assembly." Erich Gummerer, CEO TechnoAlpin AG, Bolzano, IT |

At its headquarters in Bolzano, Technoalpin AG, the world's market leader in artificial snowmaking, relies on a lighting solution by Zumtobel. In the production areas, SCUBA moisture-proof luminaires have been installed, which at all times ensure perfect lighting conditions and reliable protection against external influences, even under the most exacting environmental conditions.

They are assisted by almost maintenance-free COPA high-bay luminaires with IP 65 protection. In the offices, ECOOS pendant luminaires provide a brilliant lighting effect that creates an exciting association with the artificial snowflakes produced by the company. The corridors are illuminated by PANOS downlights and SLOTLIGHT II light lines.

Zumtobel. The Light.

share it

-

PERLUCE

PERLUCE

-

SCUBA

SCUBA

-

PANOS

PANOS

-

ECOOS

ECOOS

-

SLOTLIGHT infinity

SLOTLIGHT infinity

-

COPA

COPA

Areas of Application

Brochure

Case Studies

- Alpla Werke(.pdf/1,3 MB)

- APAG Parkhaus (.pdf/1,1 MB)

- AVEVE logistics centre (.pdf/0,6 MB)

- Bosch Rexroth (.pdf/558 KB)

- Carraro SpA energy transfer systems (.pdf/0,9 MB)

- Centre Brügg car park (.pdf/0,8 MB)

- Ferag AG(.pdf/1 MB)

- Ferrari Classiche(.pdf/494 KB)

- Frigel AG Refrigeration systems – design – service(.pdf/0,5 MB)

- Mondelēz (.pdf/572 KB)

- SBB service facility, Oberwinterthur(.pdf/0,7 MB)

- Scania Parts Logistics(.pdf/604 KB)

- Technogym (.pdf/577 KB)

- Texel Fruit Cooperative (.pdf/0,5 MB)

Studies

- Planning, implementation and operation of a melanopically effective lighting solution in a sheltered workshop (.pdf/5.8 MB)

- Effect of changing room light on the productivity of permanent morning shift employees at an industrial workplace (.pdf/1.6 MB)

- Laboratory experiment to influence productivity through dynamic lighting effects. (.pdf/0.7 MB)